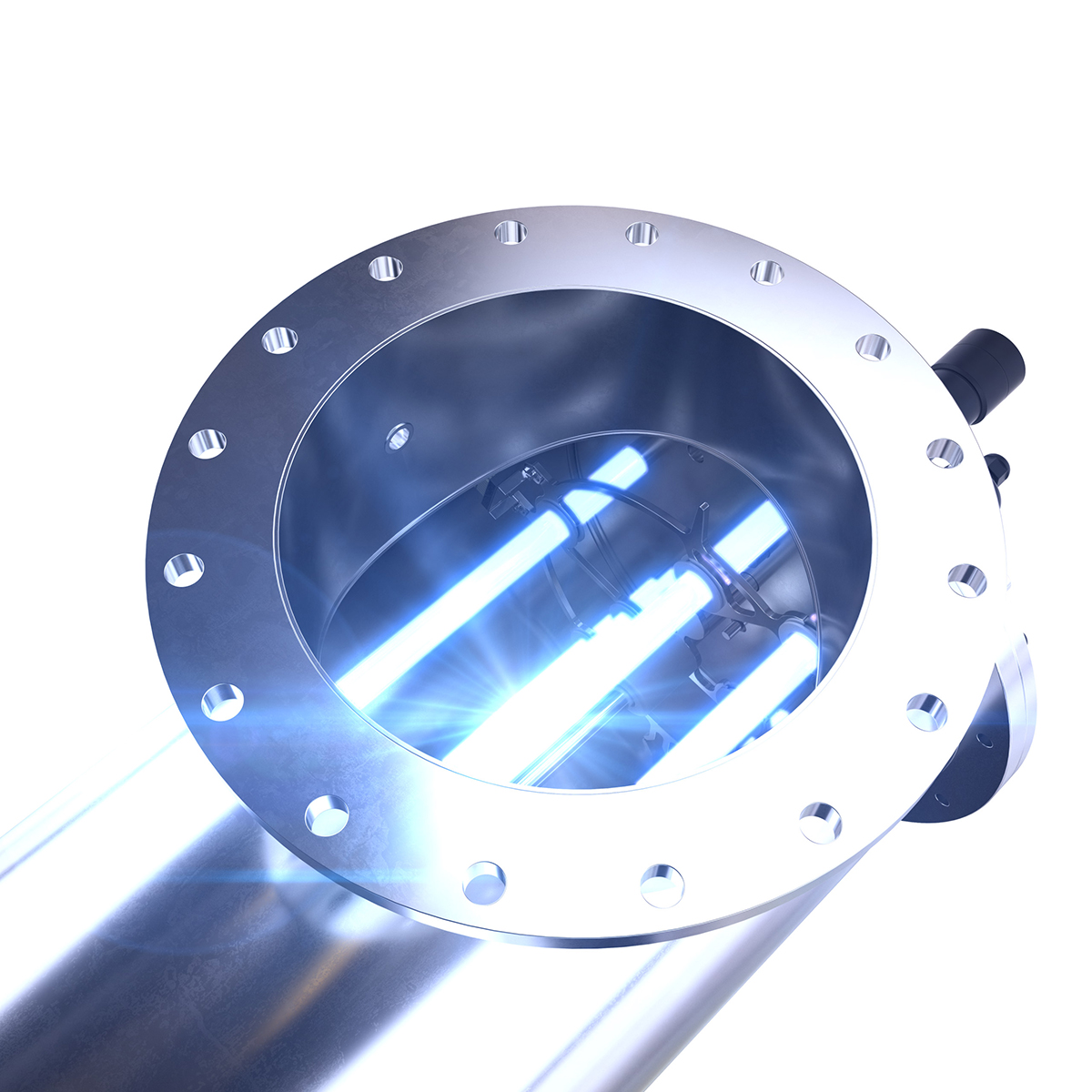

Viopure Validated Drinking Water UV System

A validated drinking water treatment solution, featuring the world’s most advanced and efficient UV disinfection technology. Tested according to the ÖNORM M 5873-1 standard, which equals or exceeds the requirements of comparable international validation criteria for UV water treatment systems, including EN 14897 – for further information please see our comparison document

The SSV series features patent-pending SWIRLFLOW™ technology, optimising the UV exposure that the water flow receives, while maintaining as much as 90% hydraulic efficiency in all water qualities. This technology also increases the effectiveness of the SSV system for low UV transmission (UVT) applications; maintaining effectiveness in conditions with as little as 70% UVT.

Electropolished stainless steel AISI 316L internal chamber walls enable up to 30% additional energy savings at higher UVT due to their reflective properties.

The system also has an automatic dose pacing feature, allowing the lamp output to be as low as 50% power consumption – while still efficiently achieving desired fluence (dosage) levels.

Automated wipers regularly clean the quartz sleeves and the UV sensor to maintain a consistent level of disinfection and monitoring

The touch-screen interface features full data logging and offers complete operator control of the UV system, either on-site or from a remote location. The controls can also be integrated with SCADA layouts and modified where required by our technical partner software engineers to meet your custom requirements.

Product Features

- ÖNORM M 5873-1 – 3rd party bioassay validation

- SWIRLFLOW™ technology enabling 90% hydraulic efficiency

- CFD optimised for minimum head loss

- Automatic dose pacing to deliver unrivalled efficiency

- Wiper system to maintain consistent treatment levels

- High-grade electropolished stainless steel AISI 316L chamber internal walls for increased efficiency (up to 30% energy saving)

For further information about our validated UV water treatment systems please get in touch

EN 14897 and ÖNORM Validation Comparison

Side-by-side criteria for international validation criteria, for expert guidance contact our head office – info@darouv.co.uk

Criteria | EN14897: | ÖNORM M 5873-1:2001 | Notes |

|---|---|---|---|

| Sensor measurement uncertainty is subtracted in % the from flow rate | ÖNORM factors 15-17% tolerance for sensor inaccuracies, EN 14897 does not factor for this | ||

| Sensor measurement required for both disinfection and bacterial testing | EN testing only requires a sensor for disinfection testing and has no requirement for bacterial treatment testing. ÖNORM requires a sensor to analyse both disinfection and bacterial treatment, additionally ÖNORM has higher technical requirements for the sensor | ||

| Wide angle sensor measurement required | Using ÖNORM compliant, wider (160°) measuring angle sensors allows preparation of both EN and ÖNORM test standards. EN does not specify a minimum measuring angle | ||

| Normalization of the flow to 40 mJ/cm² | To meet exactly 40 mJ/cm² is not possible during testing – ÖNORM allows extrapolation of the flow rate | ||

| Flow is only released if all lamps are functional and prescribed minimum irradiance is reached | ÖNORM also requires display of warning for wiper malfunction (if present), falling below the irradiance warning threshold and falling below the minimum irradiance. Control panel must also display the lamp operating time and on/off cycles | ||

| Testing procedure | Each flow rate is correlated to a specific UVT. Testing is conducted with highest flowrate and highest UVT, lowest flow rate and lowest UVT and a minimum of one flowrate / UVT in the central region of the operating range | ||

| Minimum test runs | Each test point (flow/UVT) is carried out in two different worst-case scenarios. All tests are then repeated (double determination). ÖNORM limits the factor between the lowest and highest test points (between 3 and 5 times depending on required maximum flow rate), so in general ÖNORM applies more rigorous test conditions | ||

| Construction and material requirements | ÖNORM requirements meet or exceed all criteria of EN 14897 – Section 4.2 | ||

| Minimum reduction equivalent fluence (REF) | Equal requirement: 40 mJ/cm² minimum. ÖNORM allows for normalisation between 40 mJ/cm² and 60 mJ/cm² and factors UV sensor tolerances for calculating the flow table | ||

| Operation | ÖNORM stipulates more stringent ongoing maintenance of UV systems. This includes the requirement for annual reference measurements and recalibration of the UV sensor. The vendor is responsible for training of the staff for operating and maintaining the UV system and the operator is required to keep a detailed operating log |

Key:

![Red cross circular symbol]() Not Required

Not Required

![green matches performance circular symbol]() Required

Required

![Green exceeds tick circular symbol]() Higher Requirements

Higher Requirements

ÖNORM M 5873-1

The Viopure Validated drinking water UV system series has been validated by the internationally recognized Austrian standard – ÖNORM M 5873-1. This allows the drinking water series to offer ultimate security for drinking water disinfection. For comparison to the British EN14897 standard please see our useful factsheet.