Hopes Reservoir –

Drinking Water Supply

East Lothian, Scotland

Hopes Reservoir is situated in the picturesque Lammermuir Hills, East Lothian, Scotland and is operated by Scottish Water for the supply of drinking water to approximately 2,500 local residents.

The typical daily demand on the site is 2.5 million litres, with additional capacity to supply 4 million litres at times of peak demand.

As part of an ongoing water quality redevelopment strategy, Scottish Water opted for ultraviolet water treatment as a worthwhile addition to the existing infrastructure, to further increase the quality of the water supply for the local area.

The existing system flows raw water under gravity to the works from Hopes Reservoir. Prior to entering the works building the raw water is dosed with aluminium sulphate, a coagulant to form flocs and remove colloidal particles and micro-organisms from the water.

After coagulation, the water flow is divided between twelve pressure filters. This type of filter is fully enclosed and flows downwards through sand media. These pressure filters remove the flocs caused by coagulation from the water, together with any other suspended matter, impurities and bacteria. Water flows into the top of each filter before passing through the sand media. As the water passes through the sand, impurities are trapped within the voids between the grains. This causes the media to become progressively choked, as measured by the increasing pressure drop across the filter (i.e. loss of head). Clear filtered water emerges from the bottom of the filter. The sand media requires periodic backwashing to restore the filter to its original condition.

Clean filtered water leaves the building via a 12-inch pipe, which passes through the same chamber as the raw water inlet pipe. A manual isolation valve is located within the chamber. Further downstream, the filtered water is disinfected using sodium hypochlorite. Orthophosphoric acid is dosed to inhibit plumbosolvency within the distribution network before lime is dosed to pH correct the treated water. In the original configuration, the treated water then flowed to the service reservoirs where it was gravity fed to supply.

To reach the stringent levels of the water quality redevelopment strategy that Scottish Water aimed to achieve, a UV disinfection stage was added to the existing infrastructure at this final stage to further improve the water supply from the Hopes site, before the treated water flows to the local supply.

UV technology was selected as it alleviates the need for further doses of chemicals to the water, coupled with its capabilities for inactivating waterborne pathogens that are resistant to chlorine and other disinfectants (for example; Cryptosporidium and Giardia). UV also possesses other desirable traits, such as not affecting the taste, colour or clarity of the water, while achieving 4log reduction in microorganisms and harmful microbes.

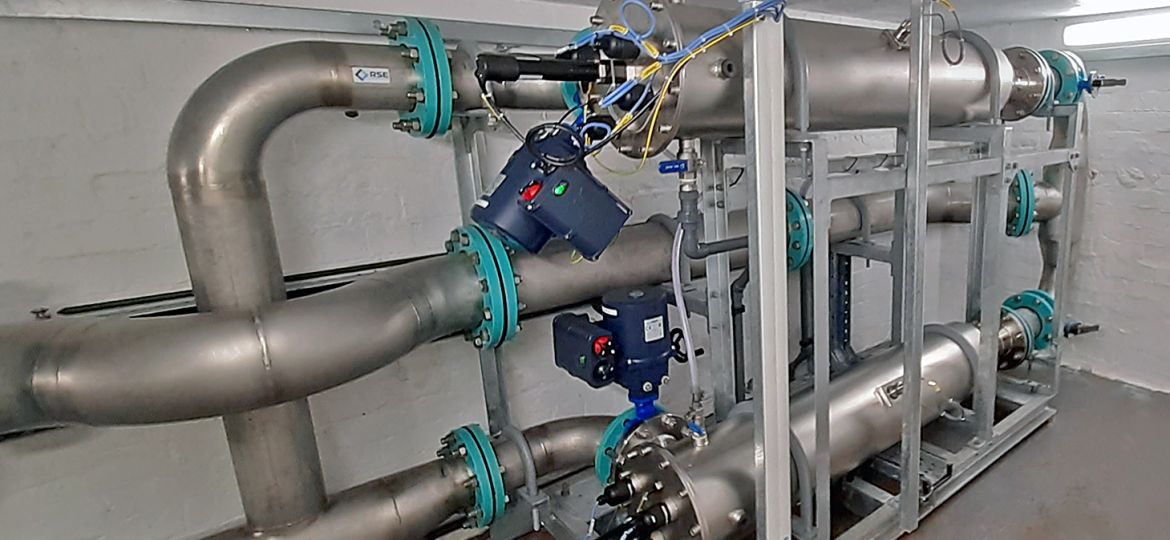

Daro UV, sole UK supplier of UltraAqua systems for the municipal sector supplied two MR4-220SSV units, which carry ÖNORM M5873-1 validation.

Ross Shire Engineering (RSE) was selected by Scottish Water to deliver the project; a tier 1 contractor with a proven track history of delivering water engineering solutions in the past.

One of the key success criteria was to bring an accelerated programme for the installation, while ensuring that the Works remained in service throughout the process. There were only two shutdowns in total during the installation, one to install the valve diversion spool piece, as well as a brief pause to allow the chosen specialised systems integrator support; iTech to update the control software for integration into the existing plant. Each of these interruptions were less than four hours in duration, keeping disruption to service to an absolute minimum.

The appointment of RSE initially took place in August 2021, with a proposed completion deadline of the end of October 2021. The project was commissioned into service and online on 21st October 2021; only eleven weeks after the first order was placed.

Another challenging aspect of the project was the compact space which was designated for the two units. RSE was instrumental in ensuring the system was planned effectively to make the best use of the limited space, ensuring the installation was a success. Daro UV, in conjunction with UltraAqua facilitated the timely delivery of the two units, while RSE began initial work on the pipework and structure. This was all pre-fabricated as a complete framework in the RSE facility to reduce time spent on site. This had the added benefit of allowing the whole system to be assembled efficiently, while minimising working in the limited confines of the installation site at Hopes Works.

The units are operated in a duty/duty configuration, which means zero run-to-waste during occasions where the isolation of one unit is required, for example to undertake servicing or maintenance. This also eliminates disinfection lead/lag responses and distributes the nominal wear that occurs on a UV system, owing largely to the UV water treatment systems having a relatively low number of moving parts – namely the wiper system. The wiper system ensures that quartz sleeves are cleaned at regular intervals with a wipe programmed to take place twice daily, this ensures the UV-C output levels from each of the four UV lamps in a reactor are kept at operational levels and prevents any deposits from building up on the quartz sleeve.

Since installation, over a year has passed with no breakdowns or failures of the equipment or lamps, highlighting the reliability that the limited number of moving parts within a UV water treatment system affords.

All stakeholders were, and continue to be immensely satisfied with the overall speed, quality and delivery of the project. Harry Cook, Capital Liaison Team Manager, Business Improvement Team, Scottish Water, commented:

“This was a complex project undertaken with Daro UV and we found them to be not only expert in their advice and guidance, but also lived up to their mission of delivering excellence as standard; in product and service delivery.

Nothing was too much trouble and they were available to discuss specific nuances at all times. We’ll certainly consider collaborating with them for future UV-related projects”

Thanks to:

Client

Scottish Water, Hopes Reservoir, Scotland

Brief

Water quality improvement and redevelopment

Success Criteria

Rapid turnaround, with minimal disruption to supply

Solution

Two MR4-220SSV validated units, running in duty/duty configuration for avoidance of downtime.

Photo © Richard Webb (cc-by-sa/2.0)